Ray Lantzy

Read more

- Home /

- Zurn AquaVantage Flush Valve Troubleshooting Guide

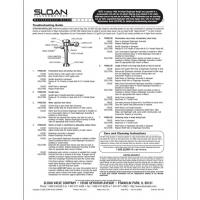

Zurn AquaVantage Flush Valve Troubleshooting Guide

-

1. Valve will not operate.

- A. Stop valve is closed.

- Open stop valve.

- B. Supply valve is closed.

- Open supply valve.

-

2. Insufficient volume of water to adequately siphon fixture.

- A. Stop valve isn't open enough.

- Open stop valve for desired volume of water.

- B. Urinal trip mechanism installed in wrong kit, urinal for closet.

- Replace urinal part with proper closet valve part.

Zurn AquaVantage Triple Filter Diaphragm Kits

Zurn AquaVantage Triple Filter Rebuild Kits - C. Insufficient volume or pressure at supply

- If guages are not available to measure supply pressure or volume of water at the valve, completely remove the working parts and open the stop valve to allow water to pass through the empty valve. If the supply is adequate to siphon the fixture, the guide ring (#17) may be removed from the guide assembly to provide additional flow. Should this prove unsatisfactory, steps should be taken to increase the pressure and/or supply.

-

3. Flush valve shuts off to quickly

- A. Damaged or punctured diaphragm.

- Install new P6000-EUR or P6000-ECR replacement kit to remedy the problem

Zurn AquaVantage Triple Filter Diaphragm Kits

Zurn AquaVantage Triple Filter Rebuild Kits

-

4. Valve is short flushing.

- A. Cylinder guide assembly and diaphragm assembly are not tight.

- Screw into two assemblies hand tight.

- B. Enlarged bypass orifice

- Install the new P6000-ECA, P6000-EUA replacement kit to remedy the problem

Zurn AquaVantage Triple Filter Diaphragm Kits

Zurn AquaVantage Triple Filter Rebuild Kits - C. Urinal trip mechanism (blue #13) in closet flush valves.

- Install closet trip mechanism (white #13)

Zurn P6000-EC13 Trip Mechanism Relief Valve (for Water Closets)

-

5. Valve is flushing too long not shutting off.

- A. Trip mechanism not seating properly due to material between trip mechanism and retainer disc.

- Disassemble parts and rinse thoroughly.

- B. By-pass orifice is plugged or partially plugged.

- Examine by-pass orifice and clean if necessary being certain not to enlarge orifice opening

Zurn AquaVantage Triple Filter Diaphragm Kits

Zurn AquaVantage Triple Filter Rebuild Kits - C. Line pressure is not adequate to force trip mechanism to seal.

- Pressure is inadequate or has dropped below minimum operating range. Steps should be taken to increase the line pressure.

- D. Cracked cover.

- Replace cover with new.

Zurn P6000-L Plastic Inside Cover

-

6. Water splashes out of fixture.

- A. Supply volume is more then is necessary.

- Adjust downward on control stop.

- B. Lime accumulation on vortex or spreader holes of fixture.

- Remove the lime build up.

-

7. Flush is not considered quiet.

- A. Control stop may not be adjusted for operation.

- Adjust the control stop for quiet operation keeping in mind the fixture evacuation requirements.

- B. Fixture may be contributing to noise.

- Check noise created by fixture by placing a cover over the bowl opening to separate valve noise from bowl noise. If it is determined the fixture is to noisy, consult with fixture manufacturer.

- C. Piping system may be source of noise.

- High pressure in the system can sometimes be controlled by the stop valve. Other sources of noise may be the absence of air chambers and shock arrestors, loose pipes, improper size pipes, etc. In these cases, the building engineer should be consulted.

-

8. Handle assembly leaking.

- A. Handle assembly is not tight.

- Tighten handle assembly.

Zurn P6000-MK Handle Repair Kit

Zurn P6000-M9 Handle Seal

Zurn P6000-M10 Handle Gasket

-

9. Water drips from the chrome cap.

- A. P6000-L inside plastic cap is cracked.

- Replace P6000-L plastic cap

Zurn P6000-L Plastic Inside Cover

Rating

thank you for the good service and kindness to help in such a kind way.

Ron I

Read more

Read less

Rating

"Thank you for checking my price and adjusting. Just made me a lifetime customer!"

Terry Foley

Read more

Read less

Rating

Mallory was great, she helped search for hydrant keys even when I was sure what we needed ... outstanding customer service. Jeff J.

Jeff Johnson

Read more

Read less

Rating

Absolutely the best customer service I've ever seen with a company. I'm a facilities manager so I deal with a lot of people and she was an absolute joy to speak with.

Gary

Read more

Read less

Rating

hi Mallory

You are amazing, I am from the Middle East. I speak English with difficulty and I have a lot of spelling. But you are really amazing. I am very happy to deal with you. I am one of your strongest supporters.

Awad Salem

Read more

Read less

Rating

You made it very easy to order over the phone. Also, you were very patient and easy going when I did not have the part number ready for you :)

Tammy D - Oklahoma City, OK

Read more

Read less

Rating

Hi. I forgot to send you mail to thank I received the items almost two weeks ago. I am so happy doing business with you. You are great! Best Wishes.

Awad A

Read more

Read less

Rating

All of you were super helpful, thorough and knowledgeable. Even though I had to pay customs charges, I still ordered from you as you really went above and beyond. Thanks for your help!

Mary

Read more

Read less

Rating

Thank you Mallory!! You are amazing! I am going on the website right now and placing the order for everything. I cannot tell you how much I appreciate your assistance!

Marla J.

Read more

Read less

Rating

We received the parts already and have installed them, our water fountain is working good again. Thanks for your help with this.

Alan

Read more

Read less

Rating

Mallory, spout was received today and looked great. We installed the replacement spout today! It looks great.

Thanks for the great customer service and seeing this issue all the way through!

Arnie Richardson

Read more

Read less

Rating

You are wonderful Shawn! Thank you again. Happy holidays and wonderful 2017 for you and yours.

Luis D.

Read more

Read less

Rating

Thanks for all of your help, it’s been really easy to work with you.

Gilberto T.

Read more

Read less

Rating

I needed to order several random parts for an obscure Kohler/Sloan pressure tank system. Katrina helped me in the live chat.

She really hung in there, found what I needed, and posted links for me to click on and ensure that the parts were likely correct. I appreciate her help. I took a lot of her time for parts that are not all that valuable, but important to me. It would have been easy for her to become inpatient, but she hung in there, found what I needed, and checked things which were a little picky in terms of exactly what was included.

Take he to lunch on me! (Really, tell her that a customer was very pleased and wanted to take time to say so.)

Val

Read more

Read less

Rating

Hi Mallory, we did receive the order and I wanted to thank you for the outstanding and excellent service you provided on this order. From the beginning of the order, to the delivery, you helped with updates and information that was very helpful and beneficial for our customer. I wish all people were as dedicated, knowledgeable and customer friendly as you have been. I will definitely continue to work with you and I look forward to placing my next order coming up soon. Again, thank you for updates and accuracy of your delivery time for this order. Excellent Job!

John

Read more

Read less

Rating

Hi Mallory

I just wanted to thank you for all of your help !!!!! The install was fairly simple with the exception of having to change the P trap location in order to fit the new foot control ... but it works great!

I know where I will go for any plumbing issues I may run in to!! I have already referred your company to 3 of my friends who are facilities managers with different company's \. Thank You again.

Jim E.

Read more

Read less

Rating

Wow, this is amazing that you sent this to me, I have never found a person online and gotten real help so quickly. Thanks so much, have a good weekend.

Holly M - Glenview, IL

Read more

Read less

Rating

I would not hesitate to deal with Kully in the future. Am very impressed with your professionalism and efficiency.

Henry

Read more

Read less

Rating

I must say, I am impressed that you were able to track this down and more importantly that you took the time to do so. Really appreciate your providing the parts breakdown, this is a big help.

Alan L.

Read more

Read less

Rating

I would like to give a big "thank you" to Mallory.

She was very helpful in helping me find a replacement cleanout cover for our facility here in Alaska.

I inquired with a couple different vendors for this part, and only Mallory actually followed up with me. She did what she said she would do in a timely fashion. Unfortunately, good customer service like that has become difficult to find.

Thank you Mallory!

Andy

Read more

Read less

Rating

Excellent service!! Products as described and fast shipping.

Mayelis Estribi

Read more

Read less

Rating

The Halsey Taylor water fountain at the church was streaming the water to fast and to long and when I Chatted with Mallory she was very helpful by downloading the owners manual for me and telling me how to adjust the pressure from the outside. I'm so thankful for this sight and If I need any parts in the future I will come to this sight first. Thank you for making my job easier!!!

Tommy Hicks

Read more

Read less

Rating

I rated you a 5. I would have given you folks a 10 but 5 was your highest rating you show. Just a little background for this testimonial. I have been dealing with Flushmate Customer Service for over two weeks. On 2/11/2018 I called in a problem with my tank wouldn't stop or flush. The young lady was super nice and tried to fix the problem with a few steps. It still wouldn't stop running. She said she would send me out a new cartridge and It should arrive in about 3 days. Bingo it did as promised. However the repair only lasted a day. I called back on 2/22/2018 and spoke to another gracious young lady. While my tank was not one on their recall she still said she would send me out a whole new tank. I received it on 2/27/2018. I called my plumber and he said he couldn't come till 3/4/2018. I scheduled it with him. I then discovered Flushmate had DIY videos so I checked it out. After several missteps and several hours of knuckle busting I just completed the task at 4a.m. All seems to be working and I'm about to try and get a few winks. In closing let me thank everyone I dealt with for going above and beyond in customer service..

james drummond

Read more

Read less

Rating

Good Afternoon,

Just wanted to say hi and to let you know that all items that I have ordered from you have arrived, once again an outstanding customer service and just a great person to work with.

Thank you

Dave

Read more

Read less

Rating

That's great thanks so much. I will not hesitate to order parts from Kully Supply next time.

Phil

Read more

Read less

Rating

The customer service reps that I spoke with were polite and went above and beyond to track down the information I was looking. Seamless interaction, absolutely phenomenal.

Christopher

Read more

Read less

Rating

Dear Shealyn,

Thanks for your response and here is what I think I need. Karaley I knew it was only a matter of time with her ability to treat people someone would see that. She truly is a great person and I have enjoyed getting to know her. I hope you and I will have the same type as well.

David M.

Read more

Read less

Rating

Shealyn B. was wonderful to work with! She took the time help us understand what we needed, her responses were quick and informed, and she always had a courteous attitude. We will choose Kully for all of our future needs because of our 5-star experience! Thank you!

Allison Endicott

Read more

Read less

Rating

You were very helpful in getting the correct part ordered and I should probably check with you in the future if I have any questions about what to order.

Bob W

Read more

Read less

Rating

Managers always here when things go wrong but rarely do they when they go right. Just wanted to give a pat on the back to Jessica (unfortunately I don't know her last name) who helped me through your online chat function today. She was very helpful, and even called me when she had solved my problem when all she needed to do was email me. That's a great employee you have there. She was courteous, helpful, knowledgeable and represented your company very well. Has made me a customer for my plumbing needs. Give her a bonus or at least a public "atta boy" (or girl in this case)!

Bob

Read more

Read less

Rating

Very satisfied with the attention and professionalism of Mallory. I'll always call Kully Supply.

Ernesto

Read more

Read less

Rating

Wow your web site is impressive. I will definitely keep your contact information handy for future use.

Curtis

Read more

Read less

Rating

Thank you so much for the information from Haws Corp. That was exactly what I needed to know. You have been an excellent help.

Bryan

Read more

Read less

Rating

Worked beautifully. Another successful hassle free order with Kully!

Hank S

Read more

Read less

Rating

Thank you very much. I appreciate all of your help this is exactly what I needed. Have a great week!!!

Patty P.

Read more

Read less

Rating

Shawn was super helpful and quickly informed me about the replacement parts I needed.

Ben

Read more

Read less

Rating

Thanks so much for everything. Feel free to forward this email to your supervisor, to let him/her know that you did an outstanding job today!

Ann Marie B.

Read more

Read less

Rating

Thank you for your excellent service!!!! I am shocked that the order went through as promised without any problems. I am looking forward to working with you and your company in the future.

Salvatore L

Read more

Read less

Rating

Thanks Shealynn, have a great weekend! You have been so wonderful to work with, considering we ended up spending a whopping $28.00 with Kully Supply. Please let me know if there is someone at your company who I can contact to compliment the excellent service you have provided us.

Debbie S.

Read more

Read less

Rating

Thank you for taking the time to contact the manufacturer about the exact replacement part, Mallory. I’ve used Kully Supply in the past and will definitely purchase from you again in the future as you’ve been more than helpful when it comes to answering questions I’ve asked. Have a terrific day and I look forward to contacting you again.

James

Read more

Read less

Rating

Alyssa helped me out today with great customer service! I nominate her for employee of the month!

Melissa

Read more

Read less

Rating

You are truly helpful. I am guessing they are fortunate to have you working for them. Have a great day!

Terry

Read more

Read less